You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tech PEB's Motion Simulator thread (for Racing Games and Flight Simulation)

- Thread starter PEB

- Start date

- Joined

- Apr 18, 2007

- Messages

- 11,149

- Reaction score

- 4,062

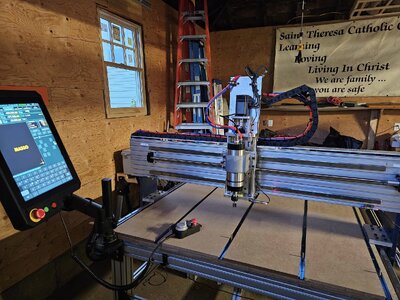

Here is current level of DIY CNC. Doing a slow homing run o. All axes.

Geez, youve got some expensive hobbies!

- Joined

- Jan 20, 2004

- Messages

- 30,798

- Reaction score

- 20,047

Not really a hobby looking to expand beyond 3D printing. I then felt like I wanted to work on signs, tabletops an doors. It also had to be WIFI capable an have a PC application to transfer files. This MASSO was the only tool that fit this bill. If I had bought this already partially assembled machine like an AVID it would have been 25k plus.Geez, youve got some expensive hobbies!

Yesterday a friend stopped by a multimillionaire oil man was retiring on Friday an wants to work with me on it. He seems more excited then me. Oh people I know stated with 1 3D printer now have up to 40 plus of them in just 2 years.

That business is expanding like crazy as well as custom milling. My friend recently had a birthday his wife bought him a picnic table with his last name cut by hand onto the table. He said she paid over 500 dollars he was like you could do the same in under two hours.

Last edited:

- Joined

- Jan 20, 2004

- Messages

- 30,798

- Reaction score

- 20,047

Got my spindle running with water cooling.