- Joined

- Jan 17, 2010

- Messages

- 4,522

- Reaction score

- 5,488

Joel Rose

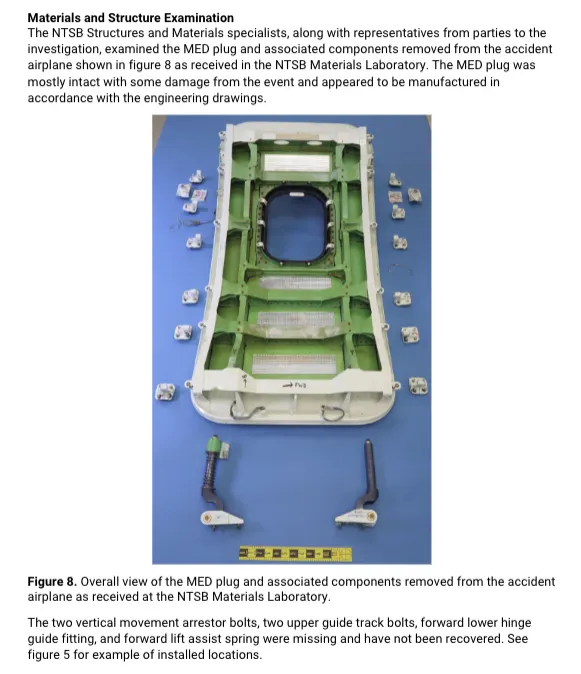

WASHINGTON — Concerns about quality control at Boeing are mounting, as new revelations from an alleged whistleblower suggest mistakes at the company's factory led to a fuselage panel blowing off an Alaska Airlines jet in midair earlier this month.

No one was seriously injured when the panel known as a door plug blew off at 16,000 feet. But the dramatic incident has renewed questions about Boeing's manufacturing processes, and whether the company is prioritizing speed and profit over safety.

Now a self-described Boeing employee claims to have details about how the door plug on that Boeing 737 Max 9 was improperly installed. Those new details, which were first reported by the Seattle Times, were published in a post on an aviation website last week.

"The reason the door blew off is stated in black and white in Boeing's own records," wrote the whistleblower, who appears to have access to the company's manufacturing records. "It is also very, very stupid and speaks volumes about the quality culture at certain portions of the business."

According to the whistleblower's account, four bolts that are supposed to hold the door plug in place "were not installed when Boeing delivered the plane, our own records reflect this."

Investigators at the National Transportation Safety Board have already raised the possibility that the bolts were not installed. The NTSB is still investigating the incident. If the whistleblower's description is accurate, investigators may be able to confirm it by looking at Boeing's records.

Boeing declined to comment on the whistleblower allegations, citing the ongoing investigation.

Those allegations came to light just as Boeing CEO Dave Calhoun was visiting Capitol Hill Wednesday, where he is seeking to reassure lawmakers and the public.

"We believe in our airplanes," Calhoun told reporters. "We have confidence in the safety of our airplanes. And that's what all of this is about. We fully understand the gravity."

NPR has not verified the identity of the whistleblower.

But this person's explanation of problems in the manufacturing process that led to the door plug blowout seem credible to Ed Pierson, a former senior manager at Boeing's 737 factory in Renton, Wash.

"It definitely seemed accurate to me," said Pierson, who now directs the non-profit Foundation for Aviation Safety. "And it doesn't surprise me, because this is the kind of stuff that we had seen, I had seen in the past."

"This is symptomatic of what happens when you rush production," Pierson said. "People are put under this kind of pressure, and they're forced to take shortcuts. And that's where these mistakes are made."

The Alaska Airlines incident is another major setback for Boeing, which was still working to rebuild public trust after the crashes of two Boeing 737 Max 8 jets in 2018 and 2019 that killed 346 people.

After the latest Alaska Airlines incident, the Federal Aviation Administration grounded 171 Boeing 737 Max 9 planes with similar door panel configurations.

Regulators at the FAA announced late Wednesday that the grounded aircraft can resume flying after a "thorough inspection and maintenance process." But the agency also imposed sweeping jet production restrictions at the company's factories.

Alaska and United Airlines have canceled thousands of flights as they waited for final inspection instructions from regulators. The CEOs of both airlines criticized Boeing in separate interviews on Tuesday.

"I'm more than frustrated and disappointed," Alaska Airlines CEO Ben Minicucci told NBC News. "I am angry."

"It's clear to me that we received an airplane from Boeing with a faulty door," he said.

That is exactly what the Boeing whistleblower alleges. Their post describes in detail how the door plug was removed for repairs and then replaced at the Boeing factory. The four bolts that hold the door plug in place should have been reattached, the whistleblower writes.

But they were not, the whistleblower says, because of communication problems between employees who work for Boeing and those who work for Spirit AeroSystems, the company that built the fuselage and door panel.

The whistleblower describes the safety inspection process at Boeing's 737 factory in Renton as "a rambling, shambling, disaster waiting to happen."

Boeing's 737 factory teams in Renton are scheduled to hold what the company is calling a "Quality Stand Down" on Thursday, allowing production to pause for a day so employees can take part in special training sessions.

But it's clear the company will have to do more than that to rebuild its reputation.

Senator Maria Cantwell (D-Wash.), the chair of the Senate Committee on Commerce, Science and Transportation, met with Calhoun on Wednesday.

"I made it clear that quality engineering and a commitment to safety always have to be the top priority," Cantwell said in a statement.

Cantwell says she plans to hold hearings to investigate the root causes of the door plug blowout.

"The American flying public and Boeing line workers deserve a culture of leadership at Boeing that puts safety ahead of profits," she said.

https://www.npr.org/2024/01/24/1226...cism-as-a-whistleblower-alleges-lapses-at-fac

WASHINGTON — Concerns about quality control at Boeing are mounting, as new revelations from an alleged whistleblower suggest mistakes at the company's factory led to a fuselage panel blowing off an Alaska Airlines jet in midair earlier this month.

No one was seriously injured when the panel known as a door plug blew off at 16,000 feet. But the dramatic incident has renewed questions about Boeing's manufacturing processes, and whether the company is prioritizing speed and profit over safety.

Now a self-described Boeing employee claims to have details about how the door plug on that Boeing 737 Max 9 was improperly installed. Those new details, which were first reported by the Seattle Times, were published in a post on an aviation website last week.

"The reason the door blew off is stated in black and white in Boeing's own records," wrote the whistleblower, who appears to have access to the company's manufacturing records. "It is also very, very stupid and speaks volumes about the quality culture at certain portions of the business."

According to the whistleblower's account, four bolts that are supposed to hold the door plug in place "were not installed when Boeing delivered the plane, our own records reflect this."

Investigators at the National Transportation Safety Board have already raised the possibility that the bolts were not installed. The NTSB is still investigating the incident. If the whistleblower's description is accurate, investigators may be able to confirm it by looking at Boeing's records.

Boeing declined to comment on the whistleblower allegations, citing the ongoing investigation.

Those allegations came to light just as Boeing CEO Dave Calhoun was visiting Capitol Hill Wednesday, where he is seeking to reassure lawmakers and the public.

"We believe in our airplanes," Calhoun told reporters. "We have confidence in the safety of our airplanes. And that's what all of this is about. We fully understand the gravity."

NPR has not verified the identity of the whistleblower.

But this person's explanation of problems in the manufacturing process that led to the door plug blowout seem credible to Ed Pierson, a former senior manager at Boeing's 737 factory in Renton, Wash.

"It definitely seemed accurate to me," said Pierson, who now directs the non-profit Foundation for Aviation Safety. "And it doesn't surprise me, because this is the kind of stuff that we had seen, I had seen in the past."

"This is symptomatic of what happens when you rush production," Pierson said. "People are put under this kind of pressure, and they're forced to take shortcuts. And that's where these mistakes are made."

The Alaska Airlines incident is another major setback for Boeing, which was still working to rebuild public trust after the crashes of two Boeing 737 Max 8 jets in 2018 and 2019 that killed 346 people.

After the latest Alaska Airlines incident, the Federal Aviation Administration grounded 171 Boeing 737 Max 9 planes with similar door panel configurations.

Regulators at the FAA announced late Wednesday that the grounded aircraft can resume flying after a "thorough inspection and maintenance process." But the agency also imposed sweeping jet production restrictions at the company's factories.

Alaska and United Airlines have canceled thousands of flights as they waited for final inspection instructions from regulators. The CEOs of both airlines criticized Boeing in separate interviews on Tuesday.

"I'm more than frustrated and disappointed," Alaska Airlines CEO Ben Minicucci told NBC News. "I am angry."

"It's clear to me that we received an airplane from Boeing with a faulty door," he said.

That is exactly what the Boeing whistleblower alleges. Their post describes in detail how the door plug was removed for repairs and then replaced at the Boeing factory. The four bolts that hold the door plug in place should have been reattached, the whistleblower writes.

But they were not, the whistleblower says, because of communication problems between employees who work for Boeing and those who work for Spirit AeroSystems, the company that built the fuselage and door panel.

The whistleblower describes the safety inspection process at Boeing's 737 factory in Renton as "a rambling, shambling, disaster waiting to happen."

Boeing's 737 factory teams in Renton are scheduled to hold what the company is calling a "Quality Stand Down" on Thursday, allowing production to pause for a day so employees can take part in special training sessions.

But it's clear the company will have to do more than that to rebuild its reputation.

Senator Maria Cantwell (D-Wash.), the chair of the Senate Committee on Commerce, Science and Transportation, met with Calhoun on Wednesday.

"I made it clear that quality engineering and a commitment to safety always have to be the top priority," Cantwell said in a statement.

Cantwell says she plans to hold hearings to investigate the root causes of the door plug blowout.

"The American flying public and Boeing line workers deserve a culture of leadership at Boeing that puts safety ahead of profits," she said.

https://www.npr.org/2024/01/24/1226...cism-as-a-whistleblower-alleges-lapses-at-fac